BRAKE DRUMS AND ROTORS

Every part of your vehicle’s brake system works together; drums and rotors are no exception. Disc brake rotors from General Motors Original Equipment (OE) are constructed with cutting-edge Ferritic Nitro-Carburizing (FNC) technology. Brake drums are carefully inspected for balance and recommended to replace your GM vehicle’s original equipment.

BRAKE DRUMS

Well-made brake drums are imperative to help keep your system running smooth, GM OE and ACDelco Brake Drums are engineered to disperse heat, helping to prolong shoe and drum life while reducing noise and vibration for a comfortable ride.

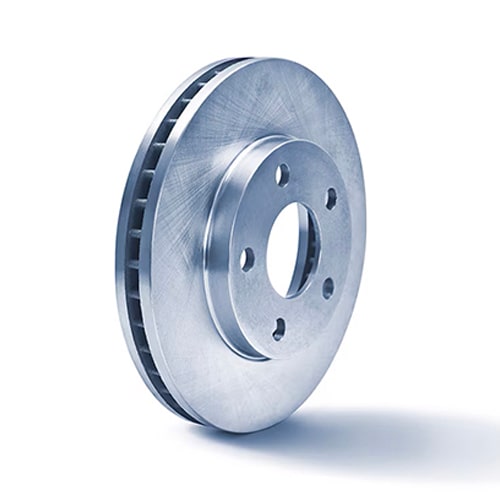

BRAKE ROTORS

ACDelco Gold Brake Rotors are designed for durability and performance, featuring a COOL SHIELD™ baked-on zinc coating that protects against corrosion from water, salt, and other elements. The rotor’s application-specific vane configuration enhances safety, reduces noise and vibration, and maximizes airflow to keep it cool. Additionally, a non-directional ground finish minimizes thickness variation, extending brake pad life and ensuring reliable braking power.

BRAKE PADS AND SHOES

GM Genuine Parts OE and ACDelco Gold and Silver Brake Pads feature premium shims, slots, and chamfers to reduce noise, vibration, and harsh braking. The brake shoes are coated with rust-resistant material for corrosion protection. These parts are specifically designed and tested for your GM vehicle’s system, ensuring smoother and quieter braking.

BRAKE PADS

GM Genuine Parts OE Brake Pads are designed to work with GM vehicle safety systems. For a high-quality alternative, ACDelco Gold Brake Pads are an excellent choice. Both GM Genuine Parts OE and ACDelco Gold Brake Pads feature zinc-coated plates for corrosion protection. If you're looking for a cost-effective option, ACDelco Silver Brake Pads offer great value, with corrosion-resistant gray backing plates and included hardware clip kits where applicable.

BRAKE SHOES

GM Genuine Parts OE and ACDelco Brake Shoes help your car run the best it can, with state-of-the-art friction-enhancing that is bonded and/or riveted to a steel backing for added strength.

AUTO PARTS WARRANTY

Most GM Genuine and ACDelco parts come with a 12-month limited warranty from the date of installation.